SAATILENE SCREEN PRINTING FABRICS

| request |

|---|

USE:

SAATILENE is a precision fabric made from monofilament polyester. As this fabric is quite insensitive to the changes in climatic conditions, SAATILENE is particularly suited to high quality work, where accuracy of register is very important. SAATILENE is a group of screen printing fabrics which includes SAATILENE HITECH and SAATILENE HIBOND-PLUS which offer high resistance under stretching and consequent lower percentage of thread lengthening and, particularly with HIBOND-PLUS, exceptional emulsion adhesion. As fabric is the control instrument for the passage and deposit of ink during printing, as well as the reproduction in general, in order to satisfy the needs of a range of screen printing applications, the fabric producers offer very wide ranges. From the point of view of the end user, a wide range must be available according to the type of fabric, fibre and the number of threads.

DESCRIPTION AND FEATURES:

NUMBER OF THREADS

The only way to differentiate one fabric from another is the number of threads for linear unit of measure, and as the majority of countries have adopted the metric system, the number of threads is usually expressed in cm. Almost all tables will however also show the conversion of this figure in inches.

The only way to differentiate one fabric from another is the number of threads for linear unit of measure, and as the majority of countries have adopted the metric system, the number of threads is usually expressed in cm. Almost all tables will however also show the conversion of this figure in inches.

Example:

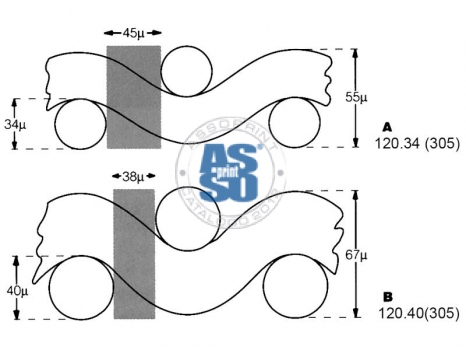

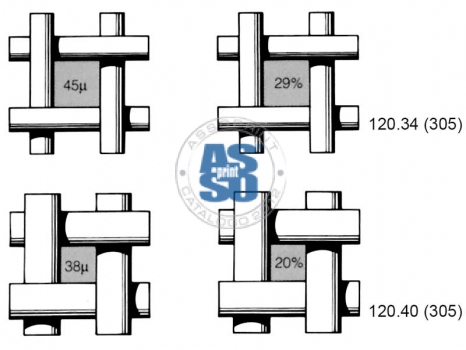

Saatilene 120.40 (305).

Saatilene 120.40 (305).

Saatilene: monofilament polyester.

Saatilene: monofilament polyester.

40: diameter of the thread expressed in microns.

40: diameter of the thread expressed in microns.

(305): number of threads per inch.

(305): number of threads per inch.

Finer fabrics are normally woven with a smaller thread diameter, while fabrics with a lower number of threads per cm. are produced with thicker threads. The ink deposit and consumption are directly influenced by the number of threads, as the ink must pass through the fabric. Some particularly absorbent surfaces therefore need more ink to pass through the fabric, for example in textile printing or on porous material, where it is logical to choose a fabric with a lower number of threads. However, it must be remembered that the fabric is the only image support, and the number of threads must therefore be able to build a sufficient support for the finer details which are to be reproduced.

Finer fabrics are normally woven with a smaller thread diameter, while fabrics with a lower number of threads per cm. are produced with thicker threads. The ink deposit and consumption are directly influenced by the number of threads, as the ink must pass through the fabric. Some particularly absorbent surfaces therefore need more ink to pass through the fabric, for example in textile printing or on porous material, where it is logical to choose a fabric with a lower number of threads. However, it must be remembered that the fabric is the only image support, and the number of threads must therefore be able to build a sufficient support for the finer details which are to be reproduced.

It is therefore necessary to make a compromise between the deposit, consumption of ink and image definition. In conclusion, fabrics with the highest number of threads per cm. are more expensive due to the greater technical needs during production.

It is therefore necessary to make a compromise between the deposit, consumption of ink and image definition. In conclusion, fabrics with the highest number of threads per cm. are more expensive due to the greater technical needs during production.

THREAD DIAMETER

The majority of fabric types can be produced with different thread diameters. The thread diameter measurement is always shown in microns, as the extrusion instruments for thread production are calibrated in microns. The factors to be taken into consideration for the choice of the thread diameter most suited to the type of fabric which is needed to be produced are the following:

The majority of fabric types can be produced with different thread diameters. The thread diameter measurement is always shown in microns, as the extrusion instruments for thread production are calibrated in microns. The factors to be taken into consideration for the choice of the thread diameter most suited to the type of fabric which is needed to be produced are the following:

A smaller thread diameter will lead to a relatively wider mesh opening and will therefore be more suited to the reproduction of finer details. On the other hand it will be less resistant to chemical washing agents or the rough surfaces of some supports during the printing process.

A smaller thread diameter will lead to a relatively wider mesh opening and will therefore be more suited to the reproduction of finer details. On the other hand it will be less resistant to chemical washing agents or the rough surfaces of some supports during the printing process.

A larger thread diameter will reduce the mesh opening, creating difficulty in the reproduction of fine works or works which have very small woven points. Thanks to a higher mechanical and chemical resistance, a larger thread diameter makes for a longer lasting screen frame. In the ceramics printing industry, for example, large thread diameters are preferable to smaller ones due to the aggressiveness of the pigment particles in the ceramic paste.

SAATILENE is a precision fabric made from monofilament polyester. As this fabric is quite insensitive to the changes in climatic conditions, SAATILENE is particularly suited to high quality work, where accuracy of register is very important. SAATILENE is a group of screen printing fabrics which includes SAATILENE HITECH and SAATILENE HIBOND-PLUS which offer high resistance under stretching and consequent lower percentage of thread lengthening and, particularly with HIBOND-PLUS, exceptional emulsion adhesion. As fabric is the control instrument for the passage and deposit of ink during printing, as well as the reproduction in general, in order to satisfy the needs of a range of screen printing applications, the fabric producers offer very wide ranges. From the point of view of the end user, a wide range must be available according to the type of fabric, fibre and the number of threads.

DESCRIPTION AND FEATURES:

NUMBER OF THREADS

The only way to differentiate one fabric from another is the number of threads for linear unit of measure, and as the majority of countries have adopted the metric system, the number of threads is usually expressed in cm. Almost all tables will however also show the conversion of this figure in inches.

The only way to differentiate one fabric from another is the number of threads for linear unit of measure, and as the majority of countries have adopted the metric system, the number of threads is usually expressed in cm. Almost all tables will however also show the conversion of this figure in inches.Example:

Saatilene 120.40 (305).

Saatilene 120.40 (305). Saatilene: monofilament polyester.

Saatilene: monofilament polyester. 40: diameter of the thread expressed in microns.

40: diameter of the thread expressed in microns. (305): number of threads per inch.

(305): number of threads per inch. Finer fabrics are normally woven with a smaller thread diameter, while fabrics with a lower number of threads per cm. are produced with thicker threads. The ink deposit and consumption are directly influenced by the number of threads, as the ink must pass through the fabric. Some particularly absorbent surfaces therefore need more ink to pass through the fabric, for example in textile printing or on porous material, where it is logical to choose a fabric with a lower number of threads. However, it must be remembered that the fabric is the only image support, and the number of threads must therefore be able to build a sufficient support for the finer details which are to be reproduced.

Finer fabrics are normally woven with a smaller thread diameter, while fabrics with a lower number of threads per cm. are produced with thicker threads. The ink deposit and consumption are directly influenced by the number of threads, as the ink must pass through the fabric. Some particularly absorbent surfaces therefore need more ink to pass through the fabric, for example in textile printing or on porous material, where it is logical to choose a fabric with a lower number of threads. However, it must be remembered that the fabric is the only image support, and the number of threads must therefore be able to build a sufficient support for the finer details which are to be reproduced. It is therefore necessary to make a compromise between the deposit, consumption of ink and image definition. In conclusion, fabrics with the highest number of threads per cm. are more expensive due to the greater technical needs during production.

It is therefore necessary to make a compromise between the deposit, consumption of ink and image definition. In conclusion, fabrics with the highest number of threads per cm. are more expensive due to the greater technical needs during production.THREAD DIAMETER

The majority of fabric types can be produced with different thread diameters. The thread diameter measurement is always shown in microns, as the extrusion instruments for thread production are calibrated in microns. The factors to be taken into consideration for the choice of the thread diameter most suited to the type of fabric which is needed to be produced are the following:

The majority of fabric types can be produced with different thread diameters. The thread diameter measurement is always shown in microns, as the extrusion instruments for thread production are calibrated in microns. The factors to be taken into consideration for the choice of the thread diameter most suited to the type of fabric which is needed to be produced are the following: A smaller thread diameter will lead to a relatively wider mesh opening and will therefore be more suited to the reproduction of finer details. On the other hand it will be less resistant to chemical washing agents or the rough surfaces of some supports during the printing process.

A smaller thread diameter will lead to a relatively wider mesh opening and will therefore be more suited to the reproduction of finer details. On the other hand it will be less resistant to chemical washing agents or the rough surfaces of some supports during the printing process.A larger thread diameter will reduce the mesh opening, creating difficulty in the reproduction of fine works or works which have very small woven points. Thanks to a higher mechanical and chemical resistance, a larger thread diameter makes for a longer lasting screen frame. In the ceramics printing industry, for example, large thread diameters are preferable to smaller ones due to the aggressiveness of the pigment particles in the ceramic paste.