COLOR SHOW

| request |

|---|

USE:

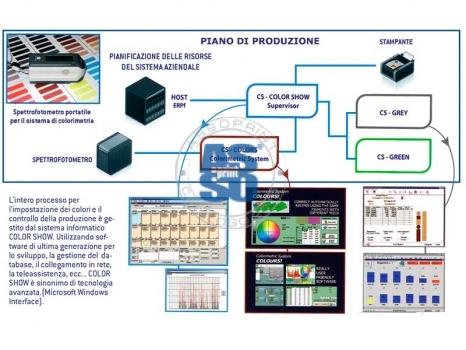

COLOR SHOW is the integrated system for the management and production of the screen printing pastes. The colorimetric system is the first step for making products in the ceramic printing field. The system automates the process of obtaining and controlling every single screen printing paste, solving the inconvenience generated from the current production systems, such as the difficulty to reproduce the screen printing pastes that develops the same colour at the saturation and luminosity level after a period of time; the difficulty in managing the raw material storage (bases and pigments) and the remaining pastes (unsold pastes); the difficulty in finding the recipe to find a specific colour after firing the tile; the difficulty in transforming bases and colours from powder into liquid form. All this occurs via a fully integrated IT system, using cutting edge software equipment in terms of development, database, networks and remote assistance. Color Show means a state of the art technology. The entire system is managed by an IT system consisting of:

CS-GREY: Is the standard package that allows the automatic dosing of single ingredients for the preparation of screen printing pastes, together with the management of recycles and levels.

CS-COLOR SHOW: Is the monitoring and centralisation program that allows the creation of a work plan, via the connection of different operating stations (host, colorimetry, tintometer, recovery stations).

CS-GREEN: Is the station referred to the management (both inlet and outlet) of pastes to be recovered (characterization, weight, storage allocation, life time, etc.).

CS-COLORS: Instrument formulation system for the spectrophotometric study of colours and quality check.

CONNECTION TO THE COMPANY HOST: to download the provisions of the production plan directly and send the production and consumption estimation to the company system.

MANAGEMENT OF THE PRODUCTION PLAN: new provisions or recipes to be produced can be set. The recipes to be produced with the relative quantity are calculated from the provisions.

SPECTROPHOTOMETER MANAGEMENT AND COLORIMETRIC CALCULATION: to recalculate the recipes from a real sample of colour and update the recipes automatically in the database.

MANAGEMENT OF RECOVERY OPERATIONS: calculation of any recovery, depending on the colours to be produced and return pastes present in the storage.

SUPERVISION OF THE TINTOMETER AND RECOVERY STORAGE: inspection and management of the recovery storage condition. Inspection of the end of production, with the chance to modify the priorities of the recipes in progress.

LOADING THE RETURN DRUMS: with automatic weighing and drum acknowledgment via bar code reading

MANAGEMENT OF STORAGE ALLOCATION: with automatic selection of the place and control of the free locations.

PRINTING NEW LABELS: with indication of the location where to position the drum.

MANAGEMENT OF THE STORAGE: the situation is displayed with the chance to correct the quantity and locations. Display of drums stored for a long time, with small quantity of paste, drums which recipe is no longer in the database and chance to remove useless drums.

DOSING: automatic, manual, restorations, additions, corrections.

DISPLAY OF THE RECIPE WHEN DOSING: components, theoretical and actual weights, tolerances, weight.

MAINTENANCE: l-O management, scale.

MANUAL RECIPE.

DOSING VALVE CALIBRATION.

ROLLERS AND MIXER MANAGEMENT.

COLOUR RECYCLE MANAGEMENT.

COLOUR STORAGE: display of the content in percentage, code, description, loading products, recycling products, dosing products.

COLOUR QUALITY INSPECTION.

INSTRUMENTAL FORMULATION: spectrophotometric reading, automatic calculation of the best formula for the colour reproducibility.

PRODUCTION STATISTICAL QUALITY INSPECTION.

SPECTROPHOTOMETER MANAGEMENT AND COLORIMETRIC CALCULATION: to recalculate the recipes from a real sample of colour and update the recipes automatically in the database.

COLOR SHOW is the integrated system for the management and production of the screen printing pastes. The colorimetric system is the first step for making products in the ceramic printing field. The system automates the process of obtaining and controlling every single screen printing paste, solving the inconvenience generated from the current production systems, such as the difficulty to reproduce the screen printing pastes that develops the same colour at the saturation and luminosity level after a period of time; the difficulty in managing the raw material storage (bases and pigments) and the remaining pastes (unsold pastes); the difficulty in finding the recipe to find a specific colour after firing the tile; the difficulty in transforming bases and colours from powder into liquid form. All this occurs via a fully integrated IT system, using cutting edge software equipment in terms of development, database, networks and remote assistance. Color Show means a state of the art technology. The entire system is managed by an IT system consisting of:

CS-GREY: Is the standard package that allows the automatic dosing of single ingredients for the preparation of screen printing pastes, together with the management of recycles and levels.

CS-COLOR SHOW: Is the monitoring and centralisation program that allows the creation of a work plan, via the connection of different operating stations (host, colorimetry, tintometer, recovery stations).

CS-GREEN: Is the station referred to the management (both inlet and outlet) of pastes to be recovered (characterization, weight, storage allocation, life time, etc.).

CS-COLORS: Instrument formulation system for the spectrophotometric study of colours and quality check.

CONNECTION TO THE COMPANY HOST: to download the provisions of the production plan directly and send the production and consumption estimation to the company system.

MANAGEMENT OF THE PRODUCTION PLAN: new provisions or recipes to be produced can be set. The recipes to be produced with the relative quantity are calculated from the provisions.

SPECTROPHOTOMETER MANAGEMENT AND COLORIMETRIC CALCULATION: to recalculate the recipes from a real sample of colour and update the recipes automatically in the database.

MANAGEMENT OF RECOVERY OPERATIONS: calculation of any recovery, depending on the colours to be produced and return pastes present in the storage.

SUPERVISION OF THE TINTOMETER AND RECOVERY STORAGE: inspection and management of the recovery storage condition. Inspection of the end of production, with the chance to modify the priorities of the recipes in progress.

LOADING THE RETURN DRUMS: with automatic weighing and drum acknowledgment via bar code reading

MANAGEMENT OF STORAGE ALLOCATION: with automatic selection of the place and control of the free locations.

PRINTING NEW LABELS: with indication of the location where to position the drum.

MANAGEMENT OF THE STORAGE: the situation is displayed with the chance to correct the quantity and locations. Display of drums stored for a long time, with small quantity of paste, drums which recipe is no longer in the database and chance to remove useless drums.

DOSING: automatic, manual, restorations, additions, corrections.

DISPLAY OF THE RECIPE WHEN DOSING: components, theoretical and actual weights, tolerances, weight.

MAINTENANCE: l-O management, scale.

MANUAL RECIPE.

DOSING VALVE CALIBRATION.

ROLLERS AND MIXER MANAGEMENT.

COLOUR RECYCLE MANAGEMENT.

COLOUR STORAGE: display of the content in percentage, code, description, loading products, recycling products, dosing products.

COLOUR QUALITY INSPECTION.

INSTRUMENTAL FORMULATION: spectrophotometric reading, automatic calculation of the best formula for the colour reproducibility.

PRODUCTION STATISTICAL QUALITY INSPECTION.

SPECTROPHOTOMETER MANAGEMENT AND COLORIMETRIC CALCULATION: to recalculate the recipes from a real sample of colour and update the recipes automatically in the database.