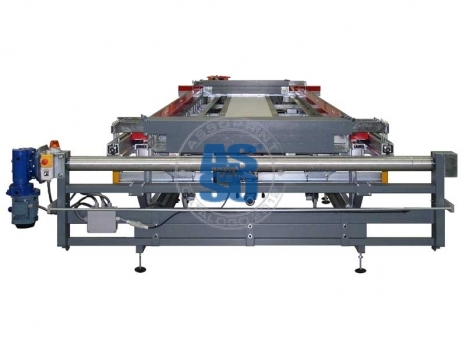

“MODULEX HP” MECHANICAL SCREEN TENSIONER

| Code | Quantity | Dimensions cm. L x P x H | Useful dimension mm | Model | Name | request |

|---|---|---|---|---|---|---|

| LSTS1100 | 1 | 410X190X90 | 1300X3000 | HP 130X300 | MODULEX SCREEN TENSIONER | estimate |

| LSTS1104 | 1 | 410X210X90 | 1600X3000 | HP 160X300 | MODULEX SCREEN TENSIONER | estimate |

| LSTS1111 | 1 | 410X230X90 | 1800X3000 | HP 180X300 | MODULEX SCREEN TENSIONER | estimate |

| LSTS1117 | 1 | 410X250X90 | 2000X3000 | HP 200X300 | MODULEX SCREEN TENSIONER | estimate |

| LSTS1201 | 1 | 130x150x90 | 1300X1500 | HP 130X150 | MODULE 1 | estimate |

| LSTS1202 | 1 | 160x150x90 | 1600X1500 | HP 160X150 | MODULE 2 | estimate |

| LSTS1210 | 1 | 180x150x90 | 1800X1500 | HP 180X150 | MODULE 3 | estimate |

| LSTS1220 | 1 | 200x150x90 | 2000X1500 | HP 200X150 | MODULE 4 | estimate |

USE:

This equipment is recommended for screen printing laboratories which require high levels of productivity and high tensioning quality even in severe working conditions. Also particularly suitable for large frame sizes.

DESCRIPTION AND FEATURES:

Though maintaining the same features as the TEM and TEC screen tensioners, MODULEX HP is supplied with a special pneumatic gripper locking system which allows to tension all types of polyester, nylon and steel fabric. Steel fabrics are widely used both for manufacturing special screen printing screens for third-firing decoration and for preparing frames for the screening of glazes and slips. Once closed, the grippers are perfectly flat, which allows subsequent machine operations to be performed without them getting in the operator’s way.

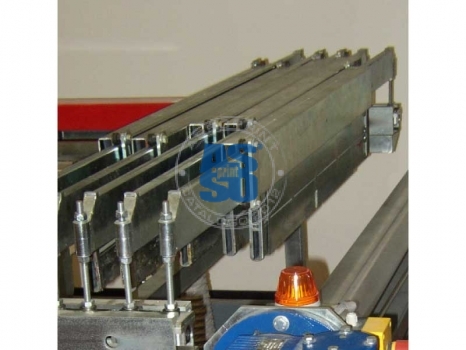

Though maintaining the same features as the TEM and TEC screen tensioners, MODULEX HP is supplied with a special pneumatic gripper locking system which allows to tension all types of polyester, nylon and steel fabric. Steel fabrics are widely used both for manufacturing special screen printing screens for third-firing decoration and for preparing frames for the screening of glazes and slips. Once closed, the grippers are perfectly flat, which allows subsequent machine operations to be performed without them getting in the operator’s way. The MODULEX HP screen tensioner features the new and exclusive RAIL SYSTEM. This system has been designed to enable the transversal frame-separating bars to be positioned with minimum physical force and maximum safety. The RAIL SYSTEM consists in two guides fixed to the sides of the screen tensioner and on which the transverse bar carriages can slide. This way the bars are kept permanently on the MODULEX HP in the park position, and can be positioned at the desired point with the greatest of ease simply by sliding them along the rails. This system overcomes the vertical encumbrance of traditional machines, which have massive support structures to suspend and move the bars.

The MODULEX HP screen tensioner features the new and exclusive RAIL SYSTEM. This system has been designed to enable the transversal frame-separating bars to be positioned with minimum physical force and maximum safety. The RAIL SYSTEM consists in two guides fixed to the sides of the screen tensioner and on which the transverse bar carriages can slide. This way the bars are kept permanently on the MODULEX HP in the park position, and can be positioned at the desired point with the greatest of ease simply by sliding them along the rails. This system overcomes the vertical encumbrance of traditional machines, which have massive support structures to suspend and move the bars. The MODULEX HP is completely motor-driven to ensure quick and balanced tensioning. Three gearmotors ensure automatic movement in the three required directions: longitudinal (warp), transversal (weft), and vertical tensioning (frame supporting table movement).

The MODULEX HP is completely motor-driven to ensure quick and balanced tensioning. Three gearmotors ensure automatic movement in the three required directions: longitudinal (warp), transversal (weft), and vertical tensioning (frame supporting table movement). All the motors are connected to safety limit switches which automatically interrupt operation when the limit positions are reached.

All the motors are connected to safety limit switches which automatically interrupt operation when the limit positions are reached. With the MODULEX HP screen tensioner it is possible to tension the fabric diagonally so as to avoid the annoying

With the MODULEX HP screen tensioner it is possible to tension the fabric diagonally so as to avoid the annoying moiré effect.

Solid painted steel frame with extremely compact modular design structure and small overall dimensions, available in various lengths but with standard length of 300 cm.

Solid painted steel frame with extremely compact modular design structure and small overall dimensions, available in various lengths but with standard length of 300 cm. All mechanical parts, in particular drive shafts, racks, gearmotors, etc. have been suitably oversized to ensure maximum reliability.

All mechanical parts, in particular drive shafts, racks, gearmotors, etc. have been suitably oversized to ensure maximum reliability. A suitable number of high-quality pneumatic pistons have been installed to ensure that the grippers have perfect grip during tensioning.

A suitable number of high-quality pneumatic pistons have been installed to ensure that the grippers have perfect grip during tensioning.  All MODULEX HP screen tensioner models are modular and can be lengthened as required by adding modules 150 cm long.

All MODULEX HP screen tensioner models are modular and can be lengthened as required by adding modules 150 cm long.  The control panel integrated with the machine frame is complete with acoustic and luminous safety devices.

The control panel integrated with the machine frame is complete with acoustic and luminous safety devices. The RAIL SYSTEM has telescopic type fabric-pressing bars which can be lengthened or shortened independently to follow the movements of the machine.

The RAIL SYSTEM has telescopic type fabric-pressing bars which can be lengthened or shortened independently to follow the movements of the machine. Large sizes are provided with the frame pretensioner which allows to maintain a high tension level on screen printing fabrics with a high number of meshes.

Large sizes are provided with the frame pretensioner which allows to maintain a high tension level on screen printing fabrics with a high number of meshes.ELECTRICAL POWER SUPPLY:

400 V, 50 Hz, 3 Ph + E.

Installed power 2.5 Kw.

For operation the machine must be connected to the compressed air supply at a minimum operating pressure of 8 bar or fitted with an independent compressor (not included).

For operation the machine must be connected to the compressed air supply at a minimum operating pressure of 8 bar or fitted with an independent compressor (not included).