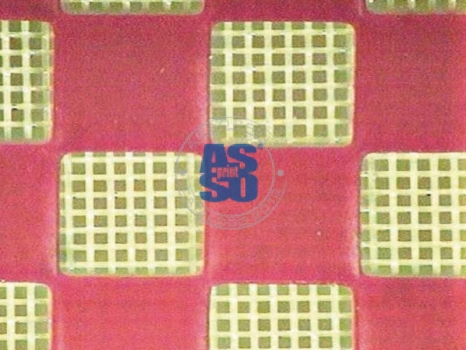

THIK FILM CAPILLARY FILM

| Code | Format | Quantity | Model | Name | PACK | request |

|---|---|---|---|---|---|---|

| CHFC0000 | 22X36 CM | 1 | THIK 100 | CAPILLARY FILM | 5 SHEETS | estimate |

| CHFC0010 | 43X36 CM | 1 | THIK 100 | CAPILLARY FILM | 10 SHEETS | estimate |

| CHFC0015 | 22X36 CM | 1 | THIK 200 | CAPILLARY FILM | 5 SHEETS | estimate |

| CHFC0020 | 43X36 CM | 1 | THIK 200 | CAPILLARY FILM | 10 SHEETS | estimate |

| CHFC0025 | 22X36 CM | 1 | THIK 300 | CAPILLARY FILM | 5 SHEETS | estimate |

| CHFC0030 | 43X36 CM | 1 | THIK 300 | CAPILLARY FILM | 10 SHEETS | estimate |

| CHFC0035 | 22X36 CM | 1 | THIK 400 | CAPILLARY FILM | 5 SHEETS | estimate |

| CHFC0040 | 43X36 CM | 1 | THIK 400 | CAPILLARY FILM | 10 SHEETS | estimate |

| CHFC0041 | 43X61 CM | 1 | THIK 400 | CAPILLARY FILM | 10 SHEETS | estimate |

| CHFC0022 | 1X2 MT | 1 | THIK 200 | CAPILLARY FILM | ROLL | estimate |

| CHFC0042 | 1X2 MT | 1 | THIK 400 | CAPILLARY FILM | ROLL | estimate |

| CHFC0043 | 1X3,5 MT | 1 | THIK 400 | CAPILLARY FILM | ROLL | estimate |

USE:

Pure red photopolymer emulsion applied on paper support making it quick and easy to use.

Can be applied as a capillary film or by lamination with Saatichem Textil PV.

DESCRIPTION AND FEATURES:

Minimum adhesion to glass during exposure.

Minimum adhesion to glass during exposure.

Quick exposure time.

Quick exposure time.

Easy to recover.

Easy to recover.

Safe and biodegradable.

Safe and biodegradable.

It may be used with a specific blue lamination emulsion (Thik Backing Emulsion) which easily determines the correct exposure time.

It may be used with a specific blue lamination emulsion (Thik Backing Emulsion) which easily determines the correct exposure time.

The film must be processed in a room with a low-power tungsten lamp or yellow light neon. Unused film must be kept in the original package. Do not bend the film in order not to ruin adhesion to the fabric. Light cotton gloves must be worn to manage the film which do not leave any fluff in order to avoid contact with the emulsion surface. Operate in a place far from sources of moisture.

The film must be processed in a room with a low-power tungsten lamp or yellow light neon. Unused film must be kept in the original package. Do not bend the film in order not to ruin adhesion to the fabric. Light cotton gloves must be worn to manage the film which do not leave any fluff in order to avoid contact with the emulsion surface. Operate in a place far from sources of moisture.

Thoroughly degrease the fabric before use. It is recommended to use a degreaser which also acts as a wetting agent for the fabric such as Saatichem Direct Prep 2. The new fabric must be degreased and roughened with Saatichem Direct Prep 1 to optimise adhesion of the stencil. After the frames have been dried, they must be kept in a dry dust-free place before being applied.

Thoroughly degrease the fabric before use. It is recommended to use a degreaser which also acts as a wetting agent for the fabric such as Saatichem Direct Prep 2. The new fabric must be degreased and roughened with Saatichem Direct Prep 1 to optimise adhesion of the stencil. After the frames have been dried, they must be kept in a dry dust-free place before being applied.

Remove any dust from the emulsion side of the film. Spray the fabric with water and then eliminate excess liquid on the perimeter of the frame to keep water from dripping onto the surface of the film which has already been applied. Bring the initial part of the film in contact with the upper part of the frame, which has been wet and positioned vertically; wait for the capillary action of the wet frame to stick the film to the fabric.

Remove any dust from the emulsion side of the film. Spray the fabric with water and then eliminate excess liquid on the perimeter of the frame to keep water from dripping onto the surface of the film which has already been applied. Bring the initial part of the film in contact with the upper part of the frame, which has been wet and positioned vertically; wait for the capillary action of the wet frame to stick the film to the fabric.

Remove excess water on the inner part of the frame near the film applied with a squeegee. Then use an absorbent tissue to remove excess water from the perimeter of the frame; then proceed to dry it in the kiln.

Remove excess water on the inner part of the frame near the film applied with a squeegee. Then use an absorbent tissue to remove excess water from the perimeter of the frame; then proceed to dry it in the kiln.

Saatichem Thik Film can be applied in different ways:

Saatichem Thik Film can be applied in different ways:

1) Position the emulsified side of the film upwards on a slightly raised surface and place the printed side of the frame on the film. Pour the required amount of Saatichem Textil PV or Thik Backing Emulsion on the upper edge of the film. Press the emulsion on the surface several times until the film sticks fully to the fabric.

2) Apply Thik Film to the fabric with the capillary method and let it dry. Apply two cross coats of Saatichem Textil PV or Thik Backing Emulsion on the squeegee side of the frame to be printed and proceed with the drying phase.

The frame can be dried with cool or lukewarm air at a temperature of 40-45°C. Perfect drying is vital for the best results. Having removed the support, let it dry another few minutes to ensure that the film is perfectly dry. It must be dried in the room protected with screened lights.

The frame can be dried with cool or lukewarm air at a temperature of 40-45°C. Perfect drying is vital for the best results. Having removed the support, let it dry another few minutes to ensure that the film is perfectly dry. It must be dried in the room protected with screened lights.

Pure red photopolymer emulsion applied on paper support making it quick and easy to use.

Can be applied as a capillary film or by lamination with Saatichem Textil PV.

DESCRIPTION AND FEATURES:

Minimum adhesion to glass during exposure.

Minimum adhesion to glass during exposure. Quick exposure time.

Quick exposure time. Easy to recover.

Easy to recover. Safe and biodegradable.

Safe and biodegradable. It may be used with a specific blue lamination emulsion (Thik Backing Emulsion) which easily determines the correct exposure time.

It may be used with a specific blue lamination emulsion (Thik Backing Emulsion) which easily determines the correct exposure time. The film must be processed in a room with a low-power tungsten lamp or yellow light neon. Unused film must be kept in the original package. Do not bend the film in order not to ruin adhesion to the fabric. Light cotton gloves must be worn to manage the film which do not leave any fluff in order to avoid contact with the emulsion surface. Operate in a place far from sources of moisture.

The film must be processed in a room with a low-power tungsten lamp or yellow light neon. Unused film must be kept in the original package. Do not bend the film in order not to ruin adhesion to the fabric. Light cotton gloves must be worn to manage the film which do not leave any fluff in order to avoid contact with the emulsion surface. Operate in a place far from sources of moisture. Thoroughly degrease the fabric before use. It is recommended to use a degreaser which also acts as a wetting agent for the fabric such as Saatichem Direct Prep 2. The new fabric must be degreased and roughened with Saatichem Direct Prep 1 to optimise adhesion of the stencil. After the frames have been dried, they must be kept in a dry dust-free place before being applied.

Thoroughly degrease the fabric before use. It is recommended to use a degreaser which also acts as a wetting agent for the fabric such as Saatichem Direct Prep 2. The new fabric must be degreased and roughened with Saatichem Direct Prep 1 to optimise adhesion of the stencil. After the frames have been dried, they must be kept in a dry dust-free place before being applied. Remove any dust from the emulsion side of the film. Spray the fabric with water and then eliminate excess liquid on the perimeter of the frame to keep water from dripping onto the surface of the film which has already been applied. Bring the initial part of the film in contact with the upper part of the frame, which has been wet and positioned vertically; wait for the capillary action of the wet frame to stick the film to the fabric.

Remove any dust from the emulsion side of the film. Spray the fabric with water and then eliminate excess liquid on the perimeter of the frame to keep water from dripping onto the surface of the film which has already been applied. Bring the initial part of the film in contact with the upper part of the frame, which has been wet and positioned vertically; wait for the capillary action of the wet frame to stick the film to the fabric.  Remove excess water on the inner part of the frame near the film applied with a squeegee. Then use an absorbent tissue to remove excess water from the perimeter of the frame; then proceed to dry it in the kiln.

Remove excess water on the inner part of the frame near the film applied with a squeegee. Then use an absorbent tissue to remove excess water from the perimeter of the frame; then proceed to dry it in the kiln.  Saatichem Thik Film can be applied in different ways:

Saatichem Thik Film can be applied in different ways:1) Position the emulsified side of the film upwards on a slightly raised surface and place the printed side of the frame on the film. Pour the required amount of Saatichem Textil PV or Thik Backing Emulsion on the upper edge of the film. Press the emulsion on the surface several times until the film sticks fully to the fabric.

2) Apply Thik Film to the fabric with the capillary method and let it dry. Apply two cross coats of Saatichem Textil PV or Thik Backing Emulsion on the squeegee side of the frame to be printed and proceed with the drying phase.

The frame can be dried with cool or lukewarm air at a temperature of 40-45°C. Perfect drying is vital for the best results. Having removed the support, let it dry another few minutes to ensure that the film is perfectly dry. It must be dried in the room protected with screened lights.

The frame can be dried with cool or lukewarm air at a temperature of 40-45°C. Perfect drying is vital for the best results. Having removed the support, let it dry another few minutes to ensure that the film is perfectly dry. It must be dried in the room protected with screened lights.